Home - Suppliers - Teledyne Hanson Research - Phoenix Dry Heat Systems

Diffusion‐cell testing made faster, easier and more economical

The Phoenix™ DB‐6 manual sampling system offers six‐cell manual sampling in a compact footprint with an advanced touch screen display. The Phoenix RDS Robotic Diffusion Station delivers fully automated sampling, collection and media replace with the ability to run up to 24 cells at once from a single computer workstation. Both systems rely on the outstanding performance of the new Phoenix Dry Heat diffusion cell, made from precision borosilicate glass, with mixer inserts engineered to produce instant homogenisation of receptor media.

Precision heating

Fast receptor media heating in 30 min or less. Programmable from 30 °C to 40 °C with a stated accuracy of ± 1.0 °C, while actual performance is typically within ± 0.3 °C.

Powerful mixing and homogenisation

The combination of grooved mixers and strong magnetic drives prevents the formation of diffusion-rate barriers directly under the membrane, thereby reducing variability of test results through nearly instantaneous homogenisation of cell contents.

Easy detection and removal of bubbles

In the Phoenix system, bubble detection and removal is fast and easy. Eliminating a common source of release-rate variability in vertical diffusion cells from trapped air bubbles beneath the membrane.

DOWNLOAD BROCHURE FOR MORE INFORMATION

Phoenix Dry-Heat Diffusion Systems

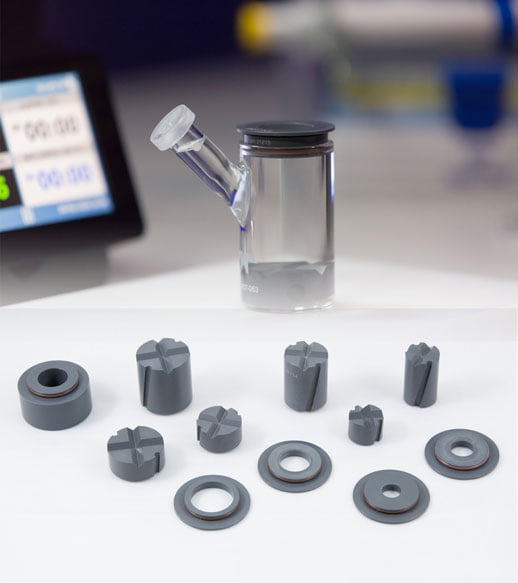

Dry Heat Cells

Phoenix dry heat diffusion cells

The new Phoenix Dry Heat Diffusion Cell is designed for precision, versatility, and ease‐of‐use in diffusion‐testing labs. In manual sampling applications, the wide opening in the arm accommodates standard pipette tips. For maximum versatility, lab analysts can choose from small, medium, or large borosilicate glass cells and, using special volume‐adjustment mixer/inserts, can obtain receptor media volumes from 10 mL to 30 mL. An array of cell cap kits accommodates all 25 mm membranes, orifice diameters from 9 mm to 20 mm, and dosage volumes from 0.25 mL to 6.2 mL. A convenient fill mark on the sampling arm indicates the cell is filled. Phoenix cells are easily inserted and removed from the heating block. Cell preparation, including dosage application, bubble detection, and bubble removal, is fast and easy.

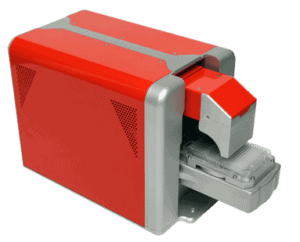

Manual Sampling

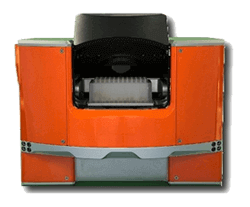

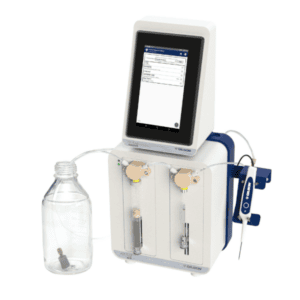

Phoenix DB-6 manual diffusion system

The Phoenix DB‐6 dry heat diffusion system provides a compact footprint for six‐cell testing. Precision heating and stirring systems contained within the block makes the system fully portable, able to be placed in any position the analyst chooses for faster, easier cell preparation. With precise control of mixing speeds from 200 rpm to 900 rpm, and temperatures from 25 °C to 40 °C, the system meets or exceeds USP <1724> specifications. An advanced colour touch screen running on an embedded single‐board computer with a built‐in SQL database and real‐time clock provides advanced monitoring, diagnostic, and reporting capabilities, user‐friendly programming and navigation, storage for up to 100 test protocols and configurable security for up to 50 users. The large, bright display allows key parameters to be seen from a distance, including speed, temperature, elapsed time and time to next sample. When sampling is due, the system alerts the operator with the cell position, a countdown timer and an audible beep. Test reports are delivered via the Teledyne Hanson serial validation printer.

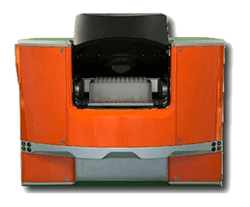

Auto Sampling

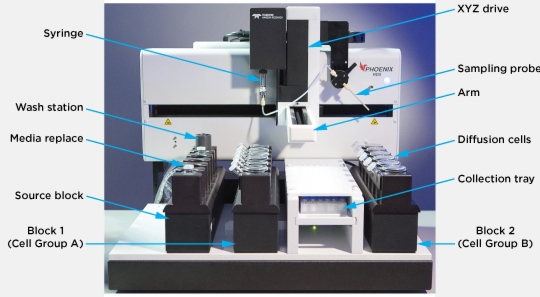

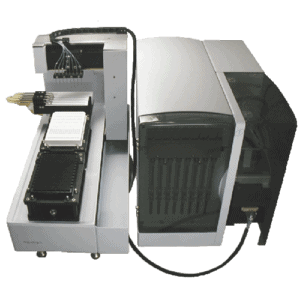

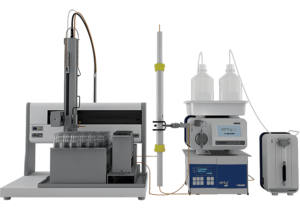

Phoenix RDS automated diffusion testing

The Phoenix RDS Robotic Diffusion Station refines the art of diffusion testing by incorporating Teledyne Hanson’s breakthroughs in four areas: diffusion cell design; heating and stirring; automated sampling and collection; and computerised control. The dry heat diffusion cell at the heart of the system delivers significantly improved test results as compared to traditional water‐jacketed, displacement‐sampling systems. The precision heating and stirring components built into each of the six‐cell blocks provide outstanding control of temperature and speed. Automatic sampling and collection are accomplished through a syringe driven probe on an XYZ platform controlled by Teledyne Hanson’s sophisticated Diffusion Master software. The automated system mimics the way sampling, collection, and media replace are performed by laboratory analysts when working manually, while simultaneously reducing the potential for variances due to procedural inconsistencies. The modular design of the six‐cell dry‐heat block allows laboratories to move smoothly between manual and automated methods when scaling to higher numbers of experiments.