We see the ability to repair, maintain and calibrate the laboratory instrumentation that we supply as a fundamental component of our overall customer support policy.

Our standard Scheduled Preventative Maintenance and Extended Warranty Agreements are designed to give you peace of mind, predictable maintenance costs and maximise system uptime.

You are welcome to discuss how these standard agreements can be tailored to suit the specific needs of your laboratory with our service and support team who have many years of industry experience and expertise. Any additional requirements you may have for installation and training, IQ/OQ, customisations (hardware and software) as well as maintenance and repairs can all be accommodated.

SCHEDULED PREVENTATIVE MAINTENANCE AGREEMENT

Our scheduled preventative maintenance agreement is intended to keep your laboratory running without having to worry about recommended instrument maintenance. It is designed to fit your laboratory’s needs and prolong the life of the instrument as well as optimise performance. We will inspect, clean, check and adjust all covered instruments and run appropriate tests to ensure that your system continues to meet the manufacturer’s performance standards.

Includes:

- Annual on-site preventive maintenance visit

- Priority phone and e-mail support

- Priority scheduling for parts and labour for onsite breakdown callouts

- 10% discount on parts, labour and travel when additional service is needed outside of the scheduled preventive maintenance visit

EXTENDED WARRANTY AGREEMENT

An extended warranty agreement is available to extend the manufacturer’s equipment warranty for an additional one year period. Extended warranty agreements are available when the system is initially purchased (save 10% off the warranty price when purchased with system) or before the standard manufacturer’s warranty expires. Extended warranties may be offered on unsupported systems that are out of the standard warranty period, subject to inspection by a Solve Scientific representative.

Includes:

- Priority on-site repair by experienced and qualified engineers

- Unlimited breakdown service calls (normal business hours)

- Includes all associated travel, labour, and parts (except for documented consumables)

- Unlimited priority phone and e-mail support

- Includes one annual on-site scheduled preventive maintenance visit as detailed above

Features

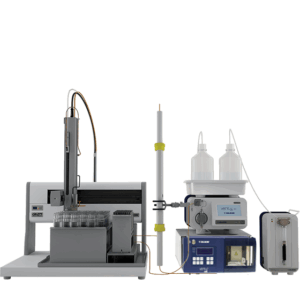

Increase your purification throughput

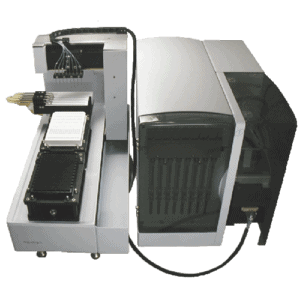

PLC 2050 and PLC 2250 Purification Systems with Autosampler are configured with a GX-241 Liquid Handler and VERITY 4020 Single Syringe Pump for automated sample injections for increased throughput. These systems allow you to queue samples and create multiple, unattended runs.

Versatile to perform advanced purification protocols

PLC Purification Systems contain a variable dynamic mixing chamber and feature two or four independent solvent inlets for binary or quaternary gradients.

Detection options

PLC Purification Systems include a conductivity / pH monitor and four-wavelength UV/VIS detection, with an optional upgrade to a diode array detector (DAD) or evaporative light scattering detection (ELSD).

Large capacity for a variety of applications

PLC Purification Systems have a large fraction capacity, containing a three-rack fraction collector with unlimited collection cycles. These systems support purification from 10 – 100 mm HPLC columns, 100 – 1000 mL CPC columns and 2.5 g – 1.2 Kg flash cartridges.

Intelligent integrated pumping

PLC Purification Systems feature a dual reciprocating pump technology, with a built-in automatic injection valve.

Specificiations

| Nanodrop II | Nanodrop Express | |

|---|---|---|

| Number of channels | 8 | 16 |

| Dispense Time 1536-well plate | < 17 sec, 1 µL reagent addition | < 8 sec, 1 µL reagent addition |

| Dispense Range: Microsolenoids 500 µL syringe 1000 µL syringe | 0.1 - 80 µL 5 - 500 µL 5 - 1000 µL | |

| Aspirate Range 500 µL syringe 1000 µL syringe | 0 - 500 µL 0 - 1000 µL | |

| Dispense Precision | 100 nL ≤ 10% 200 nL ≤ 7% 1 µL ≤ 5% | |

| Residual Volume | < 3 µL per channel | |

SYSTEMS

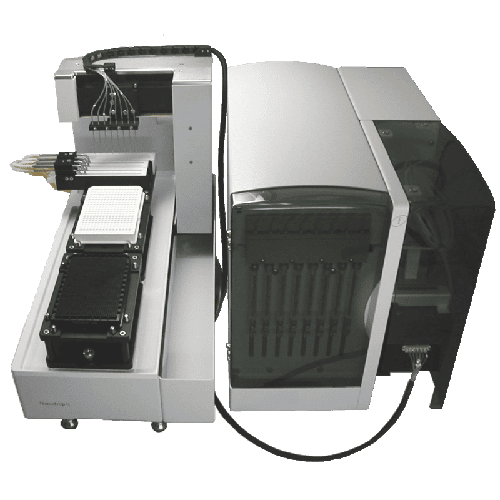

Nanodrop II

Nanodrop Express

16-channel ultra high-throughput, low-volume dispensing system

DOWNLOAD BROCHURE FOR MORE INFORMATION

Nanodrop II and Nanodrop Express

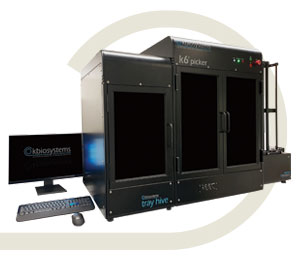

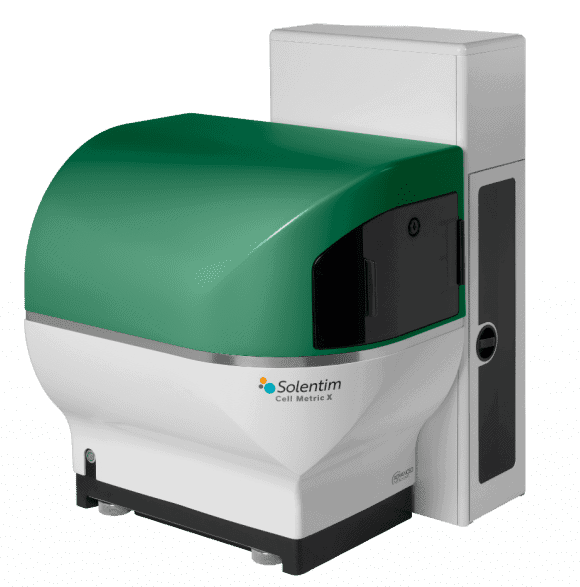

SINGLE CELL CLONING OF hiPSCs

CLD FOR PROTEIN THERAPIES

VIRUS MANUFACTURING FOR GENE THERAPY

High efficiency, high viability single cell cloning of hiPSCs for applications including development of disease models and supporting GMP manufacture of cell therapies

Generate stable cell lines that create producing novel recombinant proteins such as monoclonal antibodies or therapeutic proteins for rare diseases

From the selection of high producer clones to the development of stable vector producer cell lines, explore our simplified workflows for gene therapy applications

SINGLE CELL CLONING OF hiPSCs

CLD for Protein Therapies

Generate stable cell lines that create producing novel recombinant proteins such as monoclonal antibodies or therapeutic proteins for rare diseases

Virus manufacturing for gene therapy

VACCINE PRODUCTION USING MAMMALIAN CELLS

ENGINEERED EXOSOME PRODUCER CELL LINES

CELL ENGINEERING & PRECISION GENE EDITING

Isolate, screen and characterise attributes for clones producing novel recombinant sub-unit protein and monoclonal antibody vaccines

Establish stable producer cells for the production of engineered and cell-engineered exosomes

Optimise your drug discovery process using targeted gene editing to create stable cell lines as cellular reagents, for use in target validation, functional genomics and disease modelling

Vaccine production using mammalian cells

Isolate, screen and characterise attributes for clones producing novel recombinant sub-unit protein and monoclonal antibody vaccines