Home - Suppliers - BioNex Solutions - BeeSure Level Sensing System

PEACE OF MIND THAT YOUR SAMPLE HANDLING AUTOMATION DELIVERS WHAT YOU REQUIRE

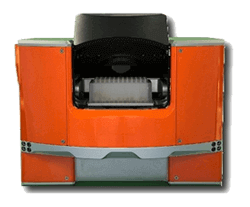

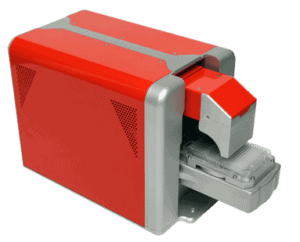

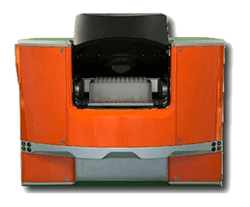

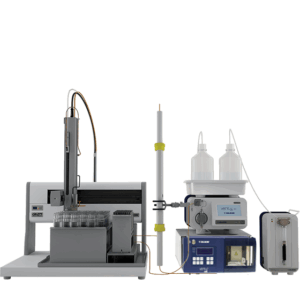

The BeeSure™ level sensing system is a quality control tool that measures the change in level within a sample vessel (microplate well, micro-tube, vial, reagent container, test tube) on the addition or subtraction of substance within the sample vessel. The substance can be either liquid or solid.

Fast and user-friendly

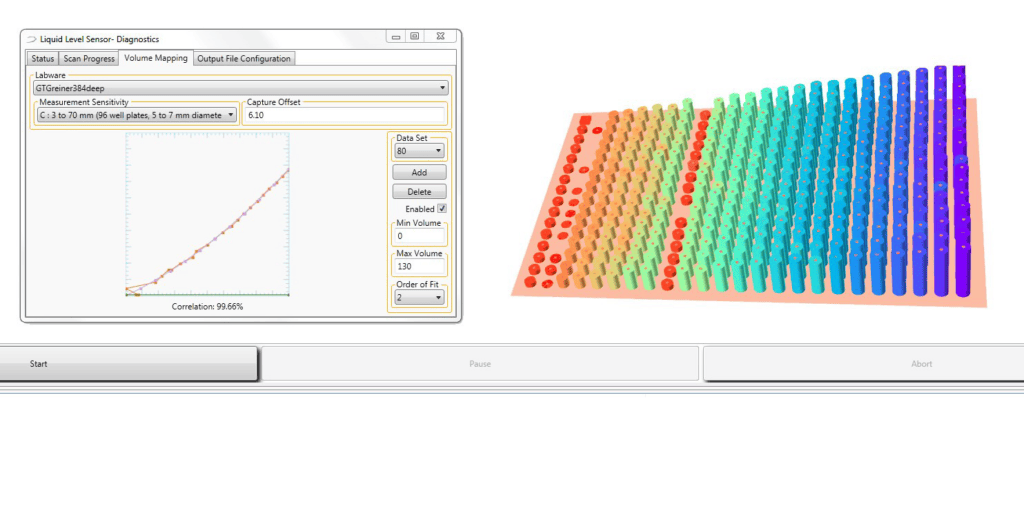

BeeSure is easy and intuitive to use, requiring no consumables for operation. BeeSure senses 96-well plates and tube racks in 30 sec and 384-well plates in 2 min, at standard precision (± 0.1 mm).

Simple operation and reporting

BeeSure produces a 3D bar graph for easy visualisation of substance volume for known vessel and estimates volume charted from a standard curve. BeeSure detects de-lidding errors, on or off or other depth anomalies, missing vials and reagent bottles.

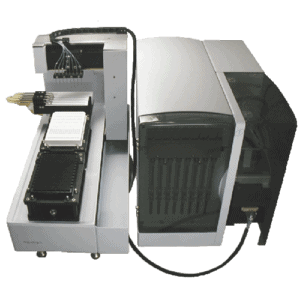

Automation compatible non-contact sensing

Non-contact sensing is easy on the BeeSure, with integration and data output to LIMS.

DOWNLOAD BROCHURE FOR MORE INFORMATION

BeeSure Level Sensing System

Features

Supports many plate formats

BeeSure can produce a topographic map for any surface within an ANSI/SBS footprint, including standard and deep 96-well plates, tube racks and 384-well plates.

Volume and vessel sensing

The BeeSure detects liquids, powders and solid substance levels in a vessel, as well as de-lidding errors, on or off or other depth anomalies, missing vials and reagent bottles.

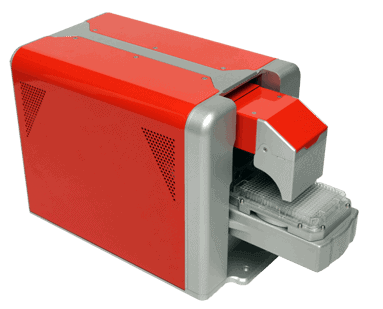

Small footprint, self-contained

BeeSure has a small footprint, only requiring one standard electrical output and a very small space on your automation platform, sample deck or lab bench.

APPLICATIONS

Validate sample transfer operations

Using a different sensing technology, BeeSure adds to life science lab automation the same function that vision QC systems provide for large scale industrial manufacturing processes.

Proactively detect a faulty dispensing system or blocked tip during pipetting operations. Verify that all the wells in a microplate were as they should have been both before and after the pipetting task in your workflow. Ensure that you have enough substance in a reagent supply vial or reservoir to complete a run with your automation system. Continuously monitor your processes to validate and document their execution before wasting high value samples and reagents because you were unaware of a system failure.

SPECIFICATIONS

| Loading | Portrait and Landscape |

| Throughput (standard precision) for: 96-well plate 96-tube rack 384-well plate | 30 seconds 30 seconds 2 minutes |

| Supported plate formats: 96-well 384-well | Most Most |

| Maximum vessel height | 51 mm |