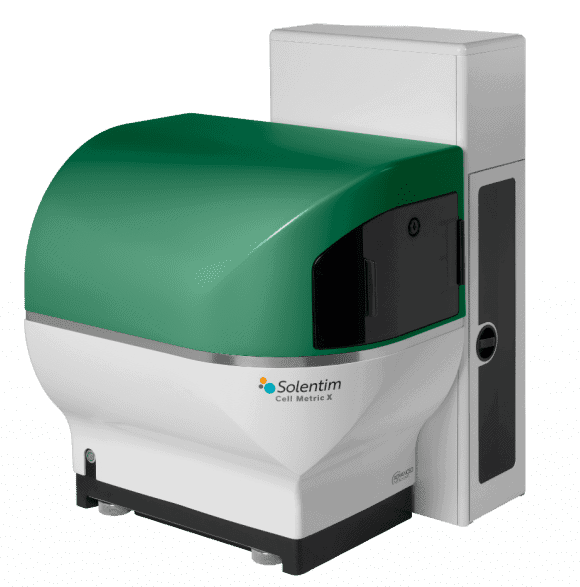

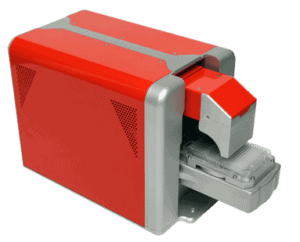

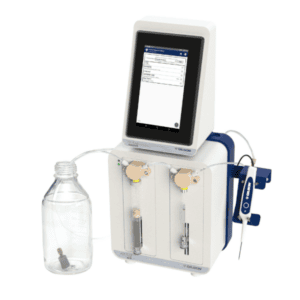

Purpose designed for industrial LC

Reliable and powerful

Flexible configurations

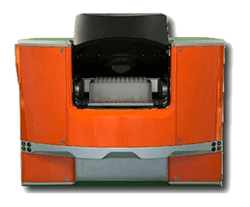

The unique design of this system allows the user to connect a large range and size of LC columns, such as HPLC, MPLC (High and Medium Pressure Liquid Chromatographic column), or CPC (Centrifugal Partition Chromatographic column) to optimise your production throughput, costs, and quality.

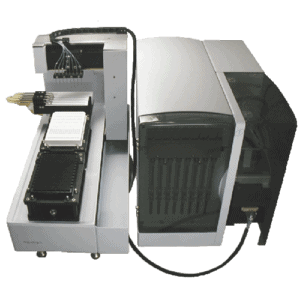

Meets industry compliance standards

VERITY® SKID LC is controlled by a certified 21 CFR part 11 chromatographic software specifically designed for production. The software allows for automatic recording of process data that can be shared via customer’s network, and customisable reports and alerts for full control of actions performed during processing.

DOWNLOAD BROCHURES FOR MORE INFORMATION

VERITY SKID LC

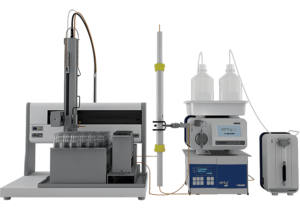

Gilson purification services

Powerful for high efficiency and throughput

The VERITY SKID LC operates at a maximum pressure of 100 bar (1450 psi), with up to 5 L/min fast elution pump available in isocratic (1 pump) or binary (2 pumps) versions.

Reliable for consistent results

The system’s elution piston pump achieves 2% flowrate accuracy and 0.5% flowrate repeatability for faster cleaning and optimised production time, along with improved reliability for production, cost-planning, and quality. Pressure transmitters, alarms, and leak sensors make for improved performance and control of the fluidic journey.

Flexible and easy-to use

The VERITY SKID LC is set on reinforced rotative wheels equipped with directional locks and brakes for easy mobility onsite. The system’s easy-to-use software allows automated stack injections and a preset list of methods for automated production. The system contains backflush valves for ascending and descending modes, which allow for safer and easier use with dual rinsing and dual modes.

Safe, robust design that is purpose built for industrial LC

The VERITY SKID LC structure is solvent-resistant and compatible with a broader range of applications. The system is CE and ATEX certified for use in a potentially explosive atmosphere and equipped with FDA compliant spare parts and consumables.