IMPROVED YIELD AND ZERO SAMPLE LOSS AT LESS COST

VERITY® CPC Systems combine a PLC Purification System with a centrifugal partition chromatography (CPC) system for high-level target compound purification. This automated, cost-effective, liquid-liquid purification technique utilises reusable, silica-free chromatographic columns to streamline your workflow and allow you to quickly isolate specific molecules with high yields and purity.

Ideal for natural product purification

Because CPC does not denature fragile molecules, it is the ideal choice for natural extract fractionation and natural compound purification. Achieve > 95% recovery with > 99% purity.

Efficient and streamlined workflow

Cost-effective and reusable CPC columns use approximately five times less solvent than more traditional columns and eliminate column replacement and silica recycling costs.

Easy to use and flexible

VERITY CPC Systems are easy-to-use and have broad applicability across natural extract, cosmetics, and pharmaceutical industries.

DOWNLOAD BROCHURES FOR MORE INFORMATION

Introduction to CPC

VERITY CPC Process System

VERITY purification systems

Features

Improved purification efficiency

Gilson’s reusable, silica-free CPC columns offer high injection capacities of milligram to multi-kilograms, resulting in 95% recoveries with 99% purity or better. This is because of the lack of irreversible absorption and denaturation of fragile molecules, which is common in other purification methods

Increased savings

CPC columns use approximately five times less solvent than most traditional columns, saving you money on solvent and disposal costs. Likewise, the reusable columns eliminate column replacement and silica recycling costs, and there is no risk of blocked or contaminated columns.

Ideal for natural products and proteins

Based on liquid-liquid purification technique, CPC does not denature fragile molecules. CPC columns tackle tough separations of complex samples in a single step without prior purification. This makes it an ideal choice for natural product isolation, protein purification, and more.

Easy to use in the lab

VERITY CPC Lab and Pilot systems with dedicated Gilson GLIDER CPC software offer flexible reporting capabilities and an intuitive touchscreen interface that enables easy method writing and modifying of parameters.

Easy to use in industry

The VERITY CPC Process system allows for automated stack injections, and a preset list of methods for automated production. It also features automatic valves for ascending and descending modes, which allows for safer and easier use with dual rinsing and dual modes.

Reliable and powerful

The VERITY CPC Process customisable rotor benefits from a new cell design and rotation speeds ranging from 100 to 1800 rpm, allowing for processing of several tons of samples per year with higher resolution. The accompanying VERITY SKID, provides a fast 3 L/min flow rate with 2% accuracy and 0.5% repeatability, which optimises production time, cost, and quality. The transmitters, alarms, and sensors present along the fluidic journey make for constant control and improved performance.

Safe and compliant

Developed with safety and compliance in mind, the VERITY CPC Process meets EU 2006/42/EU (machinery) and 2014/34/EC (ATEX) directives, with UL coming in 2021. The system is controlled by a certified 21 CFR part 11-compliant software and includes multiple, customisable securities for improved operator safety and system preservation. VERITY CPC Lab and Pilot systems and software can be adapted to customer needs with the additional detectors or activation of the 21CFR compliance option.

Systems

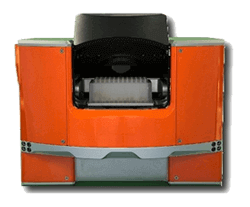

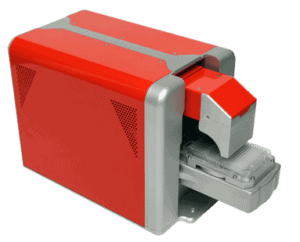

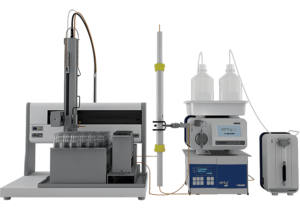

VERITY CPC Lab System

Small-scale, beyond 100 kg sample injected per year

The VERITY CPC Lab System combines a PLC Purification System with a centrifugal partition chromatography (CPC) system for high-level target compound purification.

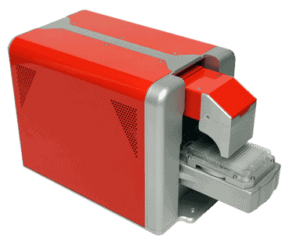

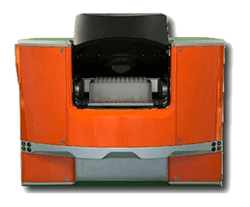

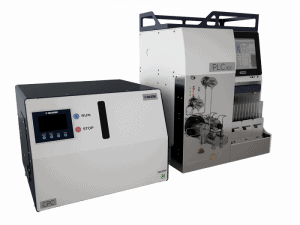

VERITY CPC Pilot System

Mid-scale, beyond 1 ton of sample injected per year

The VERITY CPC Pilot System combines the PLC 2500 Purification System with a CPC 1000 PRO for high-level target compound purification. For more efficient pumping, the VERITY CPC Pilot System can be combined with a binary injection pump.

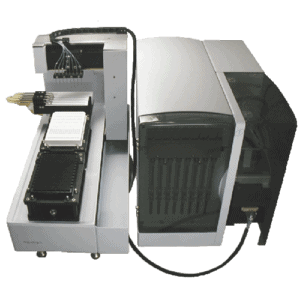

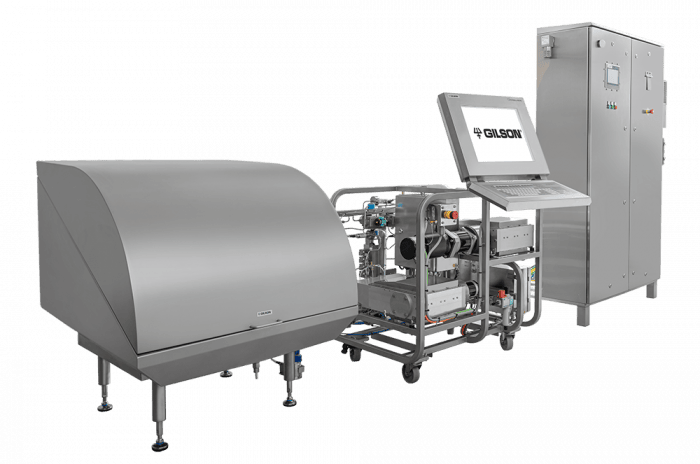

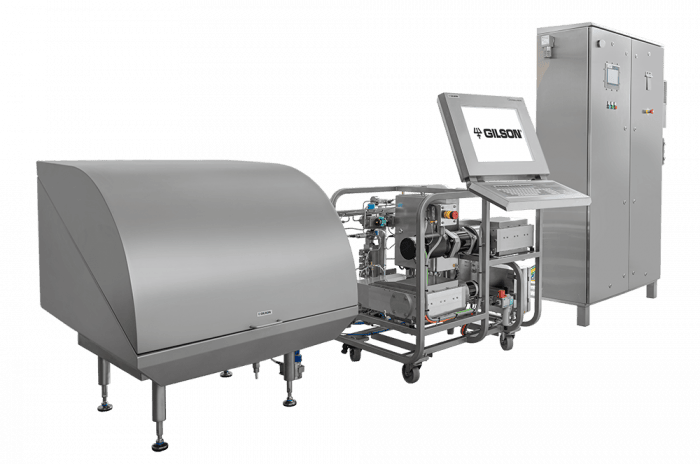

VERITY CPC Process

Large-scale, up to several tons of sample injected per year

The VERITY CPC Process system performs silica-free chromatography for process-scale purification and extraction. It combines a newly designed rotor with a capacity range of 1 – 5 L when combined with the VERITY SKID. This is the solution for annually processing tons of sample with higher resolution and the best return on investment.

This system benefits from Gilson’s unique network of Service Engineers and Application Specialists. VERITY CPC Process owners can access local support to keep their investment running at peak performance, with applications tailored after their business strategy.

VERITY CPC Process

Applications

Natural products

CPC is ideal for extract fractionation and compound purification when isolating active compounds from complex, crude, natural product extracts. Since CPC uses a silica-free liquid-liquid chromatographic technique, it does not denature fragile molecules. There is no irreversible sample adsorption to the matrix; therefore, no sample loss, resulting in higher yields. Gilson’s VERITY CPC Systems can tackle challenging separations of complex samples in a single step without prior purification, making it the ideal choice for natural products.

Cannabinoid purification

Gilson’s VERITY CPC Systems deliver high yielding, efficient and scalable extraction and purification solutions to the medicinal cannabis industry. CPC is an efficient, cost-effective alternative to traditional purification techniques, such as flash and prep HPLC. VERITY CPC Systems yield high purity cannabinoids from a crude extract and the process is easily transferrable from research to industrial GMP scale.